The U.S. Coast Guard, which has been struggling with its new ship efforts, has reportedly placed a temporary stop work order on two cutters under construction in its Heritage-class Offshore Patrol Class. Reports of the pause come a day after the Department of Homeland Security announced it had canceled a contract for another cutter in its Legend-class national security cutter and the Department has promised to overhaul the operations of the USCG under its Force Design 2028 project.

News of the pause was reported by Defense Daily which wrote that work on the third and fourth vessels underway at Eastern Shipbuilding is being delayed as issues regarding funding and delays in the timing of the program are underway. Work on the third cutter, to be named, Ingham, has been underway since mid-2022 when the keel was laid, and steel cutting is underway for number four, USCG Rush.

“We share a common goal with the U.S. Coast Guard—to deliver the Offshore Patrol Cutters as quickly and efficiently as possible,” Joey D’Isernia, CEO of Eastern Shipbuilding Group told The Maritime Executive. “We are actively working to reach an agreement that ensures the program is properly funded and can move forward without further delay. System light-offs on Hull 1 are currently underway, and despite the unprecedented challenges we’ve faced, we remain confident that our incredible workforce represents the most capable and reliable team to complete these vital national security assets.”

The Heritage-class has been highlighted as a key component of the future USCG operations. Planning for the vessels began more than a decade ago with the USCG calling the vessels “one of its highest investment priorities.” The vessels which are to be 360 feet in length with a top speed of 22.5 knots are designed to bridge the capabilities of the 418-foot national security cutters, which patrol the open ocean, and the 154-foot fast response cutters, which serve closer to shore. The Heritage-class is needed to replace the 270-foot and 210-foot medium endurance cutters that are approximately 30 and 50 years old.

The Coast Guard awarded the first preliminary design contract to three yards in 2014 and in 2016 selected the design from Eastern Shipbuilding saying it anticipated the first cutter would be delivered in 2021. However, the first steel was not cut till early 2019 and the keel was approved in 2020 followed by work starting on the second and third cutters and steel cutting for the fourth. Eastern launched the first cutter, USCG Argus, on October 27, 2023.

The second phase of the program was awarded in July 2022 with Austal contracted for one cutter and options for up to 10 more. Production on the first of the Austal-built cutters was started in August 2024 with the Coast Guard saying it would be delivered in 2027. The Coast Guard has said its goal is to build 25 Heritage-class cutters.

Congress and the Government Accountability Office have been highly critical of USCG and its management of the shipbuilding programs, and in particular the OPC and the Polar Security Cutter. Anxious to get the programs into production, GAO highlighted efforts to push the programs into construction before designs were completed, multiple design changes, and change orders to the contracts. It has resulted in delays to both programs and cost increases. Eastern was also challenged by extensive damage in the Panama City area of Florida by a Category 5 hurricane that hit the area as the program was getting started. The COVID-19 pandemic also impacted the program and contributed to coast increases.

Hours after Donald Trump took office in January, the Commandant of the U.S. Coast Guard Admiral Linda Fagan, was dismissed. Reports cited a failure of leadership on a range of issues including the problems in the shipbuilding programs. Recently, Secretary of Homeland Security Kristi Noem outlined the Force Design 28 program that calls for fundamentally overhauling the U.S. Coast Guard.

Homeland Security is moving forward with its efforts announcing yesterday that it has agreed with HII to cancel construction for the eleventh Legend-class cutter which was under construction at Ingalls in Mississippi. Parts from the program will be used instead for maintenance of the existing 10 vessels of the class.

USCG is in critical need of the new vessels to replace and upgrade its aging fleet. Congress has promised to address the under-funding issues in the shipbuilding programs while it has also demanded improvement to the programs and addressing issues such as the design problems that have plagued and delayed construction.

The Canadian Coast Guard reports the salvage teams working at the site of the grounded containership MSC Baltic III are continuing to make progress. They highlight that it remains an ongoing operation that is expected to take time.

Weather which had been a factor during the winter and early spring has improved giving the teams easier access to the vessel. In addition, one of the local mayors reported a light vehicle road was expected to be completed this week to give access for personnel into the remote area on the western shore of Newfoundland. The road is not for the removal of material from the ship.

Container removal has also begun in part to give the teams more access including to fuel tanks that they have so far not been able to reach. The Canadian Coast Guard reports approximately half of the heavy fuel has been removed in a process of heating it and pumping it to storage tanks placed on the deck of the vessel. It is then pumped into tanks on a barge and moved to Corner Brook where it is being loaded onto other MSC vessels. The Coast Guard estimates the vessel had approximately 1,600 metric tons of heavy fuel and marine gas oil onboard.

The ship grounded on the shore in a remote cove on February 15 after losing power in a winter storm. The crew was airlifted by helicopter to safety. The salvage operation has been ongoing for three months.

The salvage team placed a cargo ship, EEMS Dublin, alongside. The 6,000 dwt open hatch vessel can come alongside. It has provided a walk-to-work platform to reach the MSC Baltic III. Also, images show a crane vehicle has been put on the vessel that is being used to hoist containers from the MSC Baltic III to the deck of EEMS Dublin. The Canadian Coast Guard reports as of this week 115 containers have been removed, which is about a quarter of the boxes that were on the vessel when it grounded.

Initially, a few boxes with plastics and potential pollutants were removed. Now they are removing more boxes for access. The ship had a total of 470 containers with reports that half were empties.

The Coast Guard said the focus remains on fuel removal and mitigating pollution. Previously it reported the discovery of a few tar balls on the shoreline thought to be coming from the ship. A Coast Guard spokesperson says that the team continues to monitor the shoreline and that there have recently been some minor observations of oil including a small number of tar balls of various sizes.

The ship has sustained significant hull damage with earlier reports that the engine room and cargo holds were flooded. The Canadian Coast Guard expects to continue to see small amounts of residual oil escape from the vessel over time.

To date, there have been no public comments on how the vessel might be removed from the shoreline. The Coast Guard has previously said with the damage it was not possible to remove the vessel at this time.

Swissport has reinforced its logistics operations at EuroAirport Basel–Mulhouse–Freiburg with the addition of 800 square meters of new freight space. The expanded facility responds to rising import volumes and boosts the speed and efficiency of its cargo handling services.

To accommodate growing demand from existing carrier networks, Swissport has expanded its logistics infrastructure at EuroAirport Basel with an additional 800 m² of freight space — enabling optimized capacity and route planning for airlines already serving the airport, while also a supporting CO₂ reduction goals.

In 2024, the company handled over 47,000 tons of cargo at the site, underlining EuroAirport’s strategic role as a gateway for international goods – particularly pharmaceuticals. To support this growth by focusing on more efficient use of existing flights, Swissport has increased capacity and, in coordination with both French and Swiss customs, implemented streamlined processes tailored to the airport’s unique bi-national structure. These measures enable faster last-mile distribution and ensure smooth, efficient cargo handling.

“Located in the heart of Europe, at the crossroads of three countries, EuroAirport is a key logistics hub for global imports into Europe and pharmaceutical exports from Switzerland,” says Andreas Behnke, Head of Cargo Switzerland, Italy & France and Station Manager of Swissport Basel. “As an expert in air freight, we continuously adapt our logistics capacities to meet demand with excellence and efficiency, while upholding the highest safety and security standards.”

Swissport is also well-positioned to meet increasing demand for temperature-controlled cargo handling. At EuroAirport, 64% of its cargo activity involves the export of temperature-sensitive goods, primarily from Switzerland’s pharmaceutical industry. The IATA CEIV Pharma-certified Swissport Pharma center in Basel underscores the company’s commitment to excellence in pharmaceutical logistics. With its dedicated “cool+connect” infrastructure, the center safeguards shipments in the +2 to +8 °C range end to end, while also reducing truck movements, cutting handling times by up to 70%, and significantly lowering CO₂ emissions.

Swissport’s achievements in Basel reflect a broader global success. In 2024, the company handled a record-breaking five million tons of air cargo across its 117 air cargo centers worldwide. Strategic investments in infrastructure and technology contributed significantly to this achievement, including the refurbishment of a cargo warehouse in Johannesburg, South Africa, the opening of a third air cargo center in Liège, Belgium, to meet rising e-commerce demand, and enhancements to the “Flower Corridor” facilities in Amsterdam and Liège.

The post Swissport increases cargo capacity in Basel appeared first on Air Cargo Week.

transport logistic 2025 demonstrated what the logistics industry must—and can—achieve today. The international trade fair for logistics, mobility, IT, and supply chain management, together with air cargo Europe, was held from June 2 to 5, 2025, at the exhibition center in Munich.

It demonstrated its relevance with impressive figures: 2,722 exhibitors from 73 nations, more than 77,000 visitors from over 130 countries and regions, and an exhibition area expanded to 150,000 square meters make it by far the largest trade fair in its sector worldwide.

The share of international exhibitors rose to 65 percent (2023: 60 percent). The trade fair thus grew not only in terms of space and participant numbers, but also in its global reach. Underscoring the political and economic significance of the industry, the trade fair was officially opened by Germany’s new Federal Minister of Transport, Patrick Schnieder.

Stefan Rummel, CEO of Messe München, puts it in a nutshell: “transport logistic 2025 has impressively shown the central role that logistics plays in our connected world. It is the lifeline of the global economy. Without smooth supply chains, our everyday life would come to a standstill. I was especially pleased that the new Federal Minister of Transport, Patrick Schnieder, opened the trade fair. The significant increase in the number of participants led to a very lively and positive atmosphere. This underscores the importance of transport logistic as a world-leading trade fair.”

From autonomous transport and smart platform solutions to AI-supported control systems—ransport logistic 2025 set clear technological focal points. Current challenges and innovation potential were reflected in the event’s conference program, including panels, expert presentations and workshops. Key topics such as cybersecurity, artificial intelligence, and digitalisation set the agenda.

Stanislas Brun, Chief Cargo Officer of Etihad Cargo, summed it up: “Transport Logistics 2025 placed a clear focus on the industry’s transition towards greater digitalisation, sustainability, and innovation. Key topics included artificial intelligence, data-driven logistics, and the expansion of alternative drive systems. This year’s fair has once again set a new standard.” Tobias Jerschke, Chief Executive Officer at Kuehne+Nagel, adds, “The logistics world has found its home in Munich. In times of extreme volatility, transport logistic 2025 proves more than ever to be an authoritative platform—one that drives innovation, identifies market trends, fosters customer engagement, and delivers powerful momentum through its strong networking dynamic. For me, this event marks a boost for the industry, particularly in the key areas of technology, AI, and integrated logistics concepts.”

air cargo Europe saw a notable rise in prominence in 2025. Due to overwhelming interest, the air freight segment occupied two full exhibition halls—clear evidence of the sector’s continued systemic relevance, particularly for medical goods, e-commerce, and other time-critical deliveries.

Markus Heinelt, Director Cargo Development at Munich Airport, stated: “transport logistic, in conjunction with air cargo Europe, truly deserves its title as the world’s leading trade fair for logistics. Nowhere else do all stakeholders in the supply chain come together with such breadth and quality.” Arthur Reijnhart, Executive Director of Schiphol Commercial, adds: “air cargo plays a crucial role in keeping the Netherlands connected to the world—socially and economically. transport logistic provides a valuable opportunity to engage with partners across the industry, exchange ideas, and address shared challenges.”

transport logistic 2025 welcomed more international visitors than ever before, with a noticeable increase in decision-makers from both specialist and executive levels. Across all four days, the trade fair was marked by strong momentum, high relevance, and concrete business engagement. Its international scope was especially valued by companies operating across multiple modes of transport.

Tobias König, CCO of the Rhenus Group, emphasized: “The transport logistic trade fair is an indispensable platform for us at the Rhenus Group to connect directly with customers and partners. The conversations were of exceptionally high quality and once again proved why this trade fair rightfully holds its status as the industry’s leading event.” Dr. Frank Albers, Managing Director Sales and Marketing at KRONE Trailer, added: “For us, transport logistic is more than just a trade fair—it’s a key industry gathering with global appeal. It brings together all modes of transport to discuss future trends, challenges, and joint solutions.” Fred-Markus Bohne, Managing Partner at Panattoni, a developer of industrial and logistics real estate, adds: “transport logistic is a must-attend event. It brings together the industry’s most influential minds in one place. This year, the quality of dialog was especially notable—many of our meetings were with top-level decision-makers and were both in-depth and forward-looking.”

Whether for strategic business dialogue, setting technological direction, or in-person reunions, transport logistic 2025 was once again a central platform where the industry came together to shape the future.

Robert Howe, Managing Director of bremenports, described the atmosphere: “With around 75,000 visitors, calling transport logistic a family reunion would probably be the wrong term. But it does feel a bit like that—it’s simply that you meet many people who bring genuine passion for the transport and logistics industries. Ultimately, this is what makes transport logistic the leading trade fair in both sectors.” Alessandro Cacciola, CEO of the Andreas Schmid Group, sums it up perfectly: “transport logistic was not only a meeting place for the industry, it was also a powerful source of inspiration.”

The post transport logistic 2025 breaks records appeared first on Air Cargo Week.

Ascend Airways, UK-based ACMI (Aircraft, Crew, Maintenance, and Insurance) and charter airline, has taken delivery of its 5th aircraft – Boeing 737-8 MAX. Part of Avia Solutions Group, the world’s largest ACMI provider, the airline has also secured its Canadian Foreign Air Operator Certificate (FAOC), marking another significant milestone in its rapid expansion.

The aircraft, registered as G-ULIT, received its Certificate of Airworthiness on June 3, 2025 and will be immediately deployed onto a long-term wet lease contract. This addition represents the fourth Boeing 737-8 MAX in Ascend Airways’ fleet.

“I want to thank the entire team at Ascend Airways for their hard work and dedication in adding three aircraft over the past two months,” says Alastair Willson, CEO of Ascend Airways. “Our growing fleet positions us perfectly to meet the growing demand for reliable ACMI services in the UK and other markets with the newest generation of aircraft.”

This has been a year of significant growth for Ascend Airways, which started 2025 with just two aircraft and now operates five. The airline plans to add further Boeing 737-8 MAX aircraft over the coming months, with the goal of operating a total of eight aircraft by year-end.

The Boeing 737-8 MAX aligns with Ascend Airways’ strategy of offering the latest technology and most fuel-efficient aircraft to customers. The MAX 8 reduces CO2 emissions by 20% and has a 40% lower noise footprint compared to previous-generation aircraft, enabling customers to reduce their environmental impact when adding capacity.

In addition to fleet expansion, Ascend Airways has received its Canadian FAOC, which allows the airline to commence ACMI operations in Canada. The approval comes in time for the peak season of travel in Canada during the IATA Winter season of which Ascend Airways currently has availability on B737-8 MAX aircraft. Ascend Airways is also in the final stages of gaining it’s FAA 129 approvals which will allow the Airline to operate ACMI and Charter flights to the US and also in the process of gaining it’s IOSA approvals.

The post Ascend Airways adds 5th aircraft to growing fleet, secures Canadian AOC appeared first on Air Cargo Week.

The Mexican sail training ship Cuauhtémoc, which struck New York City’s Brooklyn Bridge on May 17, was moved this morning, June 6, to a shipyard to undergo further surveys and to begin repairs. The Mexican Navy announced it was the next part of a technical evaluation and the process to ensure the vessel once against sails as a symbol of Mexico.

The ship has remained docked at Manhattan’s Pier 36 not far from where it struck the bridge killing two sailors and injuring 19 others. There were 277 people aboard at the time. Mexico arranged to fly approximately 200 of the cadets and instructors home while keeping a crew of 77 aboard the vessel.

The NYC Emergency Management department coordinated the move which began around 0630 local time. City officials said relocating the vessel by tow through an active waterway required detailed planning. Working with the U.S. Coast Guard which established a safety zone, all vessel traffic on New York’s East River was ordered suspended for 90 minutes, including commuter ferries.

Officials said the transfer time was selected and coordinated with the tide schedule. The East River has strong currents and the early morning was reported during the slack tide period so the vessel would encounter minimal resistance. The move was executed by several tugs and images show a platform alongside the vessel. Media reports said the majority of the crew aboard was going to leave the vessel and be bussed to Brooklyn. NYC reported the vessel arrived at 0735 at the GMD Shipyard at the Brooklyn Navy Yard.

The strong currents on the river are suspected to have contributed to the accident in which the Cuauhtémoc lost control resulting in it moving north on the river and striking the underside of the bridge. It had been in New York City since May 13 and it was a ceremonial departure on Saturday evening with the cadets manning the sails and spaced in the rigging and a large Mexican flag on the stern. The tops of all three masts were broken with cadets visible hanging from the safety harnesses. Initial reports later denied said some of the cadets had fallen into the river.

After being flow to Mexico, the cadets were given psychological evaluations and counseling and time off to visit with their families. They returned to the training program after a week’s leave. Media reports said they were returning to sea for the remainder of the training program aboard a Mexican Navy vessel. Their departure had been scheduled to coincide with Mexico’s Navy Day celebrations on June 1.

Cuauhtémoc had been scheduled to fuel in the Lower Manhattan Bay after its departure and then to sail for Iceland. The vessel was to make a tour of European ports. It was to return to Mexico in November with a stop in Barbados on the return leg of its journey. Built in 1982 as a modern replica of the traditional sailing ships, the vessel is 297 feet in length and is used for training cadets and goodwill missions.

[By: Wärtsilä]

Technology group Wärtsilä will supply a conversion package featuring the company’s Fit4Power radical derating solution for the containership ‘ONE Maestro’. The Fit4Power solution optimises the power output from the ship’s engine, thereby reducing fuel consumption by on average, approximately 13 percent. This will, in turn, reduce emissions. The conversion is also expected to extend the operational life of the vessel. The ship is owned by Ocean Network Express (ONE) and managed by ONESEA Solutions Pte Ltd. The order was booked by Wärtsilä in Q1 2025.

MV ONE Maestro is a 6700 TEU containership designed and powered for speeds up to 27 knots. The vessel is currently operating at more fuel-efficient, reduced speeds in alignment with regulatory requirements, such as the IMO’s Carbon Intensity Indicator (CII). Its optimal performance will be further enhanced by Wärtsilä’s Fit4Power solution which will equip the vessel with a leaner, healthier engine through technical adjustments, such as reduced bore size. Engine efficiency is expected to improve, and the ship’s CII compliance can be extended by approximately four years. Annual CO2 savings are estimated at approximately 4,000 tons. Furthermore, cylinder lubrication oil consumption is reduced.

“Wärtsilä’s Fit4Power derating solution aligns with ONE’s operational needs. By optimising engine power output while reducing fuel consumption, Wärtsilä is supporting ONE to achieve our sustainability goals without compromising performance. This technology represents a practical approach to extending our vessel’s CII compliance as we continue to enhance our fleet operations. ONE will continue to invest in innovative technologies and our fleet, as we work towards our long-term sustainability goals.” says Hiroki Tsujii, Global Chief Officer, Head of Product and Network Division, Ocean Network Express Pte Ltd.

The conversion scope will include the supply of two new turbochargers as well as Wärtsilä’s Intelligent Combustion Control (ICC) system. The integrated technologies will be supported via Wärtsilä’s Data Collection Unit (WDCU), enabling cloud-based services and remote monitoring to optimise operability, fuel economy, and periodic maintenance. The package will also feature both Wärtsilä’s unique Expert Insight, a digital predictive maintenance service, and remote operational support. The Wärtsilä equipment is scheduled for delivery in June of this year.

“In just 25 years, shipping has a goal of reaching net zero emissions by 2050. Therefore, operators need to use all the tools in the toolbox to ensure that this transformation happens as quickly as possible. Improving engine efficiency – with solutions such as our Fit4Power solution – provides a valuable way for the industry to accelerate the decarbonisation journey of the existing fleet today,” says Stefan Wiik, Vice President, Parts & Field Service – Wärtsilä Marine.

Wärtsilä’s Fit4Power solution is a key element in the company’s committed strategy to support decarbonised shipping. Since its launch to the commercial market in Spring 2023, Wärtsilä has already retrofitted 17 vessels with the solution, with several more planned for delivery. With decarbonisation high on the maritime agenda, Wärtsilä continues to see great interest in the market for more conversions with Fit4Power.

Five years ago, at the height of the global Covid-19 pandemic, Air France KLM Martinair Cargo faced an unprecedented disruption. Rather than merely reacting to the crisis, the company chose to seize the moment as a catalyst for deep, strategic transformation – redefining its commercial strategy, elevating the customer experience and laying a solid foundation for digital leadership and sustainability in airfreight. “At the heart of our transformation was a simple but powerful commitment – to put our customers first in everything we do,” says GertJan Roelands, SVP Commercial at Air France KLM Martinair Cargo.

From a spread sheet to the industry-leading online booking and service platform

As global logistics evolved and customer expectations rose, Air France KLM Martinair Cargo recognised the growing demand for air cargo services to mirror the seamless, always-available nature of modern digital platforms. Inspired by best-in-class B2C models, the company set out to reimagine the traditional B2B cargo journey – making it transparent, controlled and simple, anytime and anywhere.

myCargo, the company’s full-service digital platform and central touch-point for customers worldwide, lies at the heart of this transformation. What began as a simple internal Excel-powered tool to generate quotes has since been developed in-house into a comprehensive quote-and-book solution. Over time, it has matured into a robust, end-to-end booking and service platform. Powered by dynamic pricing and modern revenue management systems, myCargo allows users to book, modify and track shipments in real-time. The commercial approach has also become more data-driven, with the launch of a dedicated e-acquisition team leveraging data, content and digital engagement strategies under the principle: know your customer, engage and convert. Today, 88% of all bookings are made through myCargo – an achievement that reflects both the platform’s capabilities and the degree of trust it has earned. “We consider this a strategic milestone in our transformation journey and clear confirmation from customers of the progress we’ve made,” says GertJan Roelands.

But the transformation didn’t stop here. To deliver more personalised and responsive service, the company is now launching CRM360, a global AI-powered service platform co-developed with Salesforce.

This next-generation solution ensures consistent, efficient and customised support throughout the customer journey, worldwide. Investments continue in AI-enabled solutions – such as chat, voice and priority models – providing customer service teams with cutting-edge tools, insight and expertise. “Our ambition is to offer a truly unique, next-level service experience in the industry – combining the best of human connection with technological excellence,” says Roelands.

Customer centricity at the heart of the organisation

Customer experience (CX) has been placed at the core of the organisation – not just as a department, but as a shared responsibility across all teams. A new CX framework has been introduced to ensure end-to-end journey visibility, proactively address challenges and drive continuous improvement. Complementing this, the company streamlined its product portfolio and introduced Service Level Plus – offering enhanced flexibility and value. More innovations are underway, shaped by operational insight and ongoing customer dialogue.

Our commercial transformation also required a rethinking of the organisation itself. Air France KLM Martinair Cargo reduced its regional structure from five to two area zones, simplified its hierarchy and introduced a new generation of leaders with expertise in digital, data and customer strategy. Innovation and entrepreneurial spirit are actively encouraged, with employees empowered to initiate ideas that enhance customer value within a structured portfolio management process. These changes have served to increase the company’s speed, agility and alignment with market demands.

Committed to reducing the carbon footprint of airfreight

Sustainability remains a guiding priority. In December 2020, the company launched the airfreight industry’s first Sustainable Aviation Fuel (SAF) programme, now supported by over 100 strategic partners. Through GoSAF – available directly via myCargo – customers can actively reduce emissions at a shipment level. These efforts are bolstered by fleet renewal initiatives directed at achieving zero-emission ground operations at its major hubs. While proud of the strides taken, the company remains realistic and realises there is still a long way to go. Collaboration is the key to real progress. When we join forces, we unlock new solutions and build a stronger supply chain.

Transformation leading to customer success and market leadership

Capturing the spirit of its transformation, the company launched a new brand positioning concept: Here to Connect. More than just a slogan, this reflects Air France KLM Martinair Cargo’s vision to be a leader in sustainable airfreight while passionately delivering a superior customer experience. This vision came to life in a brand film created in cooperation with the Bruut Amsterdam agency, which has won multiple awards for its message and creative impact.

The results speak for themselves. Digital bookings now account for 88% of all transactions, with the 90% milestone expected by year-end. Distribution costs have been significantly reduced. Our Net Promoter Score (NPS) – a key indicator of customer satisfaction – has improved by over 30% in five years. These achievements have solidified the company’s competitive edge and contributed to its emergence as a market leader in airfreight out of Europe.

Reflecting on this journey, GertJan Roelands elaborates: “We’re proud of our progress. We’ve gained market leadership in many areas, but we also recognise this is just the beginning. Transformation isn’t a one-off endeavour – it’s a mind-set. What we’ve achieved so far is thanks to the dedication of our diverse and talented teams, a deep commitment to our customers and our continued investment in innovation. We will keep evolving, listening and leading – with purpose – for our customers, for our people and for our planet.”

The post Air France KLM Martinair Cargo: From disruption to digital appeared first on Air Cargo Week.

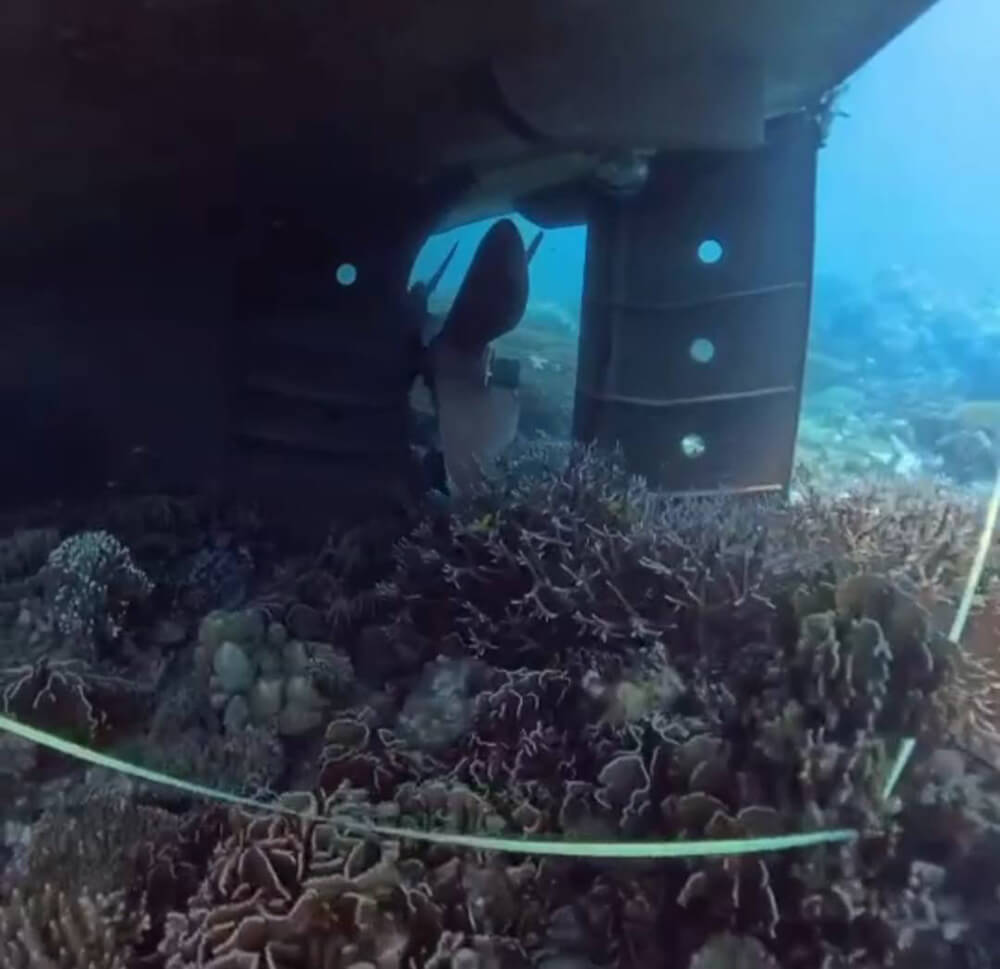

The authorities in Thailand are working to address the grounding and sinking of a rickety wooden cargo ship from Myanmar that has hit one of the country’s premier coral reefs. The vessel grounded and partially sunk damaging at least 75 meters (approximately 250 feet) of precious Blue and Deer Coral and has the potential to leak oil into the environment.

The wooden 100-tonne cargo ship named Ayar Linn sank on Sunday, June 1, after grounding on the reef in the Mu Ko Surin National Park in the Surin Islands of the Andaman Sea. Thai officials report it is one of the most famous diving and marine life viewing sites in the world. It is within the National Parks in Thailand.

The vessel stranded off Jak Bay in the northern parts of the province and then sank spilling its cargo onto the reef. It has 7,700 liters of diesel onboard.

Divers were sent to inspect the region and report a 75-meter trench of damage in the reef with the worst portions being between meters 45 and 75, where the vessel is now stuck. The coral under the vessel has been crushed and a line of coral, especially the tall species, was broken. In addition, the vessel spilled bags of cement as well as significant amounts of cardboard, rags, truck tires, hoses, and other debris that is littered on the reef.

The divers were initially attempting to seal the values on the fuel tanks. Efforts were also underway to pump the fuel from the partially submerged vessel. The Department of National Parks, Wildlife, and Plant Conservation working with other agencies called for oil booms that could also be strung to contain any fuel leaks.

They said a full salvage mission can not be carried out at this time because it is monsoon season. The danger of strong waves and winds makes any salvage operation risky. They are working with the other authorities to develop an approach for managing the situation.

The Kuraburi Police Station is also collecting relevant evidence as well as checking the ship’s documents, and entry and exit from the country. They are planning to lodge a complaint against the owner of the vessel and seek compensation.

The authorities are also asking citizens and tourists to avoid approaching the area for safety and to allow the recovery operation to proceed.

The Department of Homeland Security is reporting that it canceled the order for the eleventh Legend-class national security cutter which was to be named USCG Friedman. Production for the vessel began in 2021 at HII’s Ingalls Shipbuilding in Pascagoula, Mississippi, but the project has been dogged by concerns.

Ingalls had a sole source contract as the only builder for the class which began delivering in 2008 and was designed to replace 12 aging 378?foot Hamilton-class high-endurance cutters that have been in service for 40 years. At 418 feet long, the Legend-class NSC has a maximum speed of 28 knots and a range of 12,000 nautical miles. The tenth ship, USCG Calhoun was delivered in October 2023.

Work had begun for number 11 in May 2021. HII reported that the start of fabrication signified the first 100 tons of steel had been cut. USCG said the vessel was due for delivery in 2024 and plans called for it to be homeported in Charleston, South Carolina with four other Legend-class cutters.

“Huntington Ingalls owed us this cutter over a year ago,” said Homeland Security Secretary Kristi Noem. “This project was over time and over budget. Now the money can be redirected to ensuring the Coast Guard remains the finest, most-capable maritime service in the world.”

According to the announcement for Homeland Security, canceling the contract with HII will save the U.S. over $260 million. They have also agreed that the Coast Guard will receive $135 million in parts that will be used to retrofit, upgrade, and maintain the Coast Guard’s existing fleet of 10 Legend-class cutters.

Congress has been highly critical of the USCG’s problems with its shipbuilding projects both for the cutters and the Polar Security Icebreakers. USCG had reported to Congress that there were issues with the project saying that construction of the 11th ship had been halted since at least November 2024 with the ship 15 percent complete. It blamed “material conformance concerns,” and said that the Coast Guard and the shipbuilder were working to resolve the issue.

The Coast Guard has also planned a 12th vessel in the Legand-class. Congress was yet to appropriate funds for the vessel but some long-lead elements were reportedly being ordered.

Homeland Security highlights canceling the project will save money that can be used as part of the recently announced Force Design 2028 project to overhaul USCG operations and command structure. However, it did not address how the USCG will allocate resources for the two planned vessels which were scheduled as replacements for the older class which is now entirely decommissioned. The USCG had deferred the decommissioning of the last two Hamilton-class cutters, John Midget and Douglas Munro, to 2020 and 2021 while the rest of the class was replaced with the new cutters by 2018.